Proposing a Geotechnical Risk Index

This project set the foundations for development of a quick 3D tool that would allow early identification of geotechnical risk in an open pit design via a preliminary review of most of the factors involved in the definition of a slope stability condition, such as design geometry, rock mass strength, structural and geological condition and water pressure. It is proposed to perform an adequate processing of the previous components (prior to execution of formal stability analyses) via implementation of a FISH

routine that assigns risk indices to the geometry objects in 3DEC and allows generation and visualization of 3D contours of a variable designated as Geotechnical Risk Index (GRI) on any stage of the projected design. Formal stability analysis could then be decided based on the results of the GRI contouring, increasing the efficiency of analysis resources by focusing on the most unfavorable sectors of the pit.

Project Background

Predictive analyses are a usual requirement to validate a mine design process from the geomechanics point of view. Empirical, analytical and numerical solutions are available in order to anticipate geotechnical risk and provide mitigations when necessary.

Out of these alternatives, the empirical methods cannot be extrapolated with confidence if the basic assumptions for their development are substantially modified. Analytical methods can be used as long as the problems addressed can be reasonably assimilated to the underlying simplifications inherent to the equations developed. Numerical models can be used to explain observed physical behavior (whenever historical data is available) to calibrate its components and subsequently allow evaluating multiple possibilities of design but, despite the advance of computer speed observed in recent decades, in many cases the response time of the numerical models can be an important limitation. Therefore, this work aims to define a Geotechnical Risk Index (GRI), which was conceived as a preliminary step to any stability analysis project in order to choose candidate sectors for a formal stability analysis with any of the aforementioned methods.

In the context of this methodology, geotechnical risk will be understood as the risk to construction work (mining or civil excavations in our case) created by site ground conditions that could lead to safety and economic risks. The proposed GRI gathers the key elements commonly involved in a geotechnical stability analysis and provides a relative estimate of the risk condition for a given design. The key elements that participate in its definition are the geometric design and the geotechnical model components (geological, rock mass strength, structural and hydrogeological models). With some differences, some authors have proposed a key element assessment to perform a geotechnical hazard analysis (Castro et al., 2011). Others have adapted existing rock mass classification systems to evaluate the stability condition, such as the Slope Mass Rating (Romana et al., 2015).

FISH is an embedded scripting language that enables the user to interact with and manipulate variables into the different Itasca codes. In addition to allowing manipulation of finite difference meshes and models developed within the Itasca codes, one powerful capability of FISH is manipulation of external entities, such as wireframes representing mining geometries and the processing of arrays representing block models. These capabilities are used in the work described in the following sections, as FISH was used to develop an algorithm which allows calculation and visualization of the GRI in a tridimensional manner using the Itasca code 3DEC.

Methodology

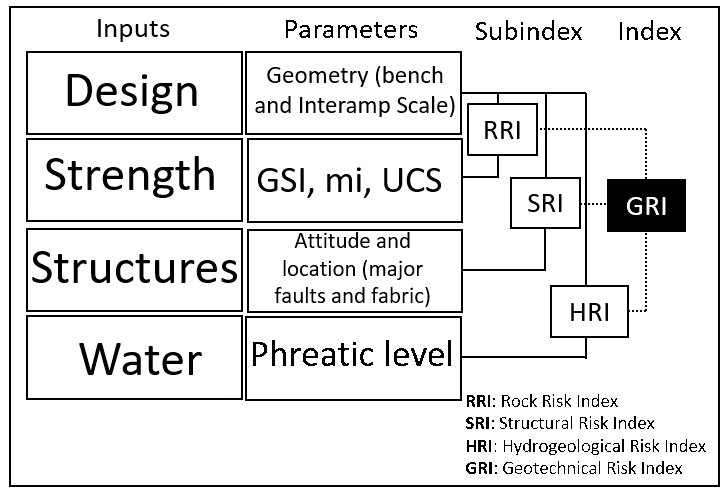

The key elements involved in stability analyses can be combined in order to define relative risk areas. The work presented here focuses on open pit slopes. However, and despite differences between the extraction methods, the concept should be equally applicable to underground mining but include aditional factors, such as the stress field condition, among others. Figure 1 shows the flow chart proposed to estimate a GRI for open pits using algorithms developed in FISH. The three components of the GRI are described in the following sections.

Rock Risk Index (RRI)

This index estimates the relative stability condition as a combination of rock mass strength and geometry of the design. In this sense, the RRI component of the GRI addresses the potential for “rock mass” controlled instabilities.

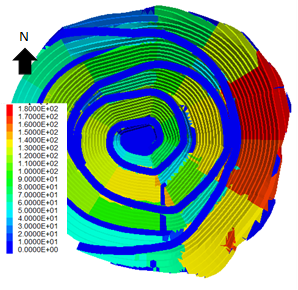

For the purposes of estimating the RRI, the tool evaluates the IRA (InterRamp Angle) and IRH (InterRamp Height) for each sector of the mesh representing the design under revision (see Figure 2). In addition, the intact rock and rock mass parameters can be uploaded directly from a geotechnical block model and then incorporated into each element of the design geometry.

Figure 3 shows the results of hundreds of generic 2D numerical model runs representing different design geometries based on IRH, IRA and 10 different rock mass strength envelopes typically observed in the practice. As a first approach to the problem, the rock mass was considered isotropic and homogeneous, the material strength changes were represented in terms of variations of UCS and the IRH-IRA combinations seek a Factor of Safety (FoS) equal to 1.3.

Considering a FoS=1.3 as an acceptable condition for inter-ramp scale stability, the tool then reviews all the combinations of IRH-IRA strength calculated in the design and provides a likely geotechnical stability condition assessment using the closest envelope curve of those shown in Figure 3. The Rock Risk Index for each geometry element in the design is then flagged as RRI=0 in the case of an acceptable condition or RRI=1 when a potential risk is identified.

Structural Risk Index (SRI)

This index evaluates the geotechnical risk due to the interaction between discontinuities and the design. It is proposed to determine the geotechnical risk level at two scales: large blocks formed by major structures such as faults, and kinematic conditions for the structural fabric commonly estimated via a structural domain model.

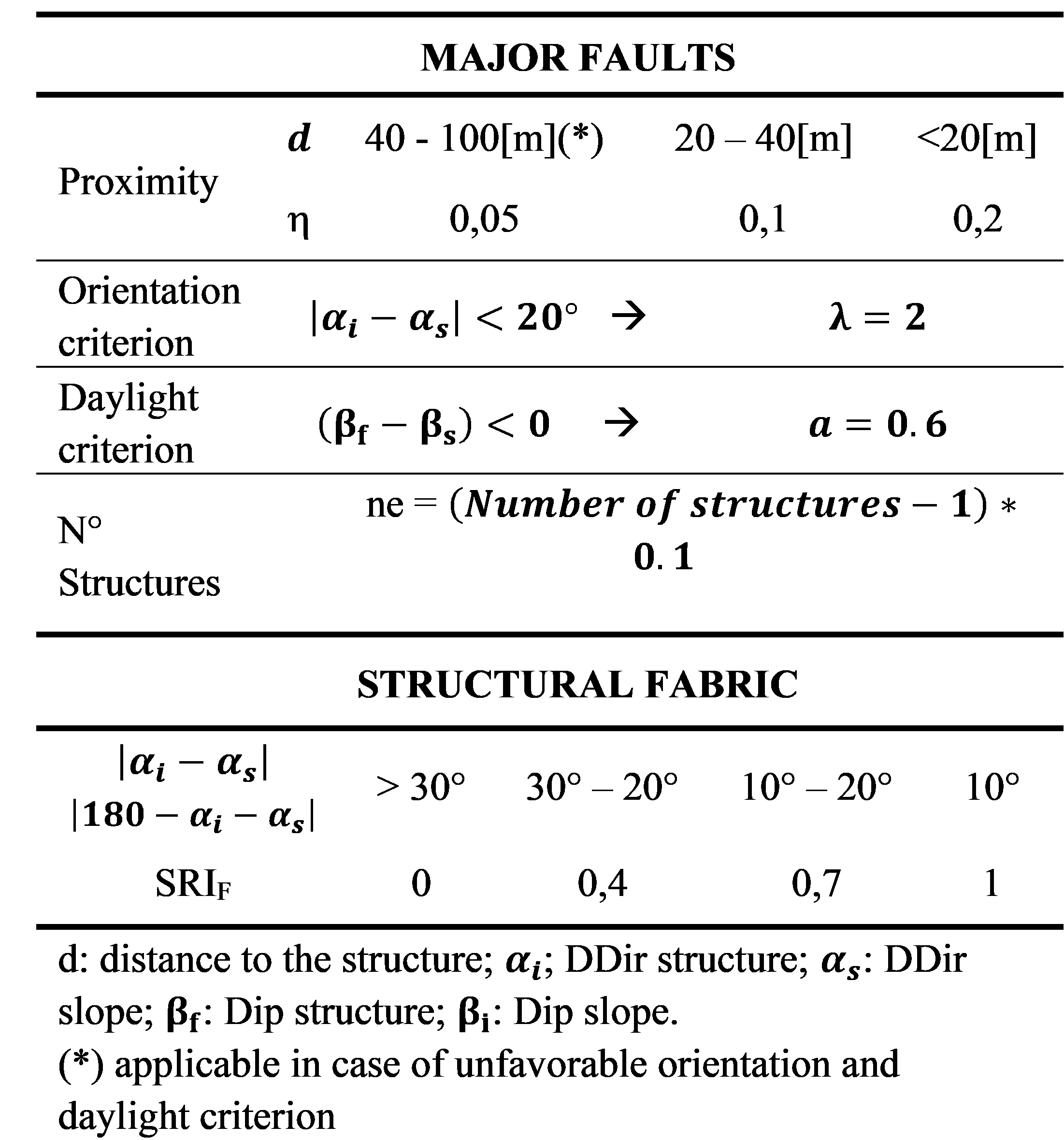

The geotechnical risk due to the interaction of large blocks with the design is evaluated using the sub-index SRIMB, and its value depends on the proximity of faults, their relative orientation and the number of structures located in the same place on the design. To asses such risk conditions, Equation 1 was developed to assign the higher value to zones located close to structures that strike parallel or nearly parallel and daylight in the slope face. Additionally, an extra coefficient was included to capture weathered zones caused by the concurrence of multiple structures.

Where η = coefficient of proximity of the structure to the slope, λ = coefficient of relative trend, a = daylight indicator and ne = fault convergence coefficient. Table 1 shows the initial values for each parameter.

Minor structures, such as joints and minor faults, are used to estimate the geotechnical risk sub-index SRIF based on its orientation with respect to the slope. The tool allows loading the structural domain volumes and identifies the sectors of the design within it. In addition, it is possible to load the statistics for orientations of the different systems per domain.

Using the values proposed by Romana (1985) as a first reference, the calculation of the sub index SRIF is shown at the bottom of Table 1.

Hydrogeological Risk Index (HRI)

The third sub-index evaluates the geotechnical impact from the hydrogeological condition observed or predicted for an excavation. It is known that the most relevant effect of groundwater on stability comes from the induced change of the effective stress, which reduces the effective strength. The HRI values are calculated based on Equation 2.

Where dnf = distance between slope surface and phreatic level and dnf,max = maximum distance between slope surface and phreatic level.

Geotechnical Risk Index (GRI)

The Geotechnical Risk Index is then obtained as a combination of the weighted sum of the sub-indices previously described and based on Equation 3.

where, pi = relative weight of the sub-index. The definition of these values is addressed in Section 3.1.

At the end of the calculation process, the algorithm produces a tridimensional contour of the GRI or any other intermediate variable or sub-index. The tool also allows the comparison of different stages of excavation or different designs to identify relative potential risks and determine candidate sectors to be evaluated in detail using formal slope stability analysis methods of any kind.

Analysis and Results

The methodology proposed here has been applied to two real cases. The first case considered the geotechnical conditions observed on site with an algorithm calibration objective. This means that once all the information necessary to calculate the GRI was available, changes in the relative weights of the sub-indices were necessary in order to match the higher risk areas obtained from GRI in comparison with the unstable areas observed at the site. Once the most appropriate relative weights were found for the first case, they were used in a second case, which is an open pit porphyry deposit as well, but with different characteristics and known, documented slope behaviors. This aims to verify if the GRI could reproduce a general behavior or if there are local geotechnical conditions that need to be taken into account and, as a consequence, would need a new calibration process.

Case 1.

Case 1 represents an open pit mine whose slope configuration consists of 15 m high benches with 65° bench face angles. The maximum inter-ramp height is around 150 m and IRAs range between 35–50 °.

The calibration process was carried out via trial and error, modifying the relative weights mentioned above. Figure 4 and Figure 6 show the GRI contours calibrated based on the areas where the mine monitoring system has shown movements (red lines).

In general, the behavior of any slope can be associated to either structural control or rock mass strength. One of the indicators to determine the most likely mechanism is the rock mass quality. Therefore, the relative weights of the indices in Equation 3 must be related to this consideration. In Case 1, a jointed rock mass with GSI>50 was considered a lower boundary for structural control, hence the relative weight for structures (SRI) should be comparatively greater. On the other hand, GSI<30 suggests rock mass control, and the RRI and HRI weights should be comparatively greater than the others.

The GRI distribution (where GRI=1 is maximum risk and GRI=0 is minimum risk) shown in Figure 4 seems to be reasonable in comparison to the mobilized areas identified by the on-site monitoring system, which indicates movement in Sector 1. The GRI in this sector is mainly influenced by the presence of several faults oriented unfavorably and a non-daylighting wedge occurrence. Added to this structural control, a poor rock mass quality is also observed (see Figure 5).

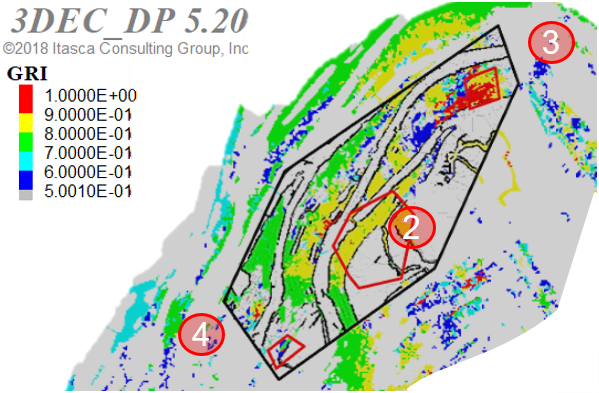

Regarding Sectors 2, 3 and 4 (see Figure 6), the GRI contour shows potential high risk sectors (GRI=0.9-1.0) mainly due to the poor rock mass quality (see Figure 7), an unfavorable groundwater condition and a fault convergence.

Case 2.

The parameters obtained from the calibration process developed in Case 1 were applied directly in Case 2 to evaluate its validity. Case 2 information comes f rom a substantially different open pit mine with a different geomechanical setting. The slope configuration consists of 15 m high benches and 70° bench face angle. The maximum inter-ramp height is around 135 m and IRAs range between 38 and 50°.

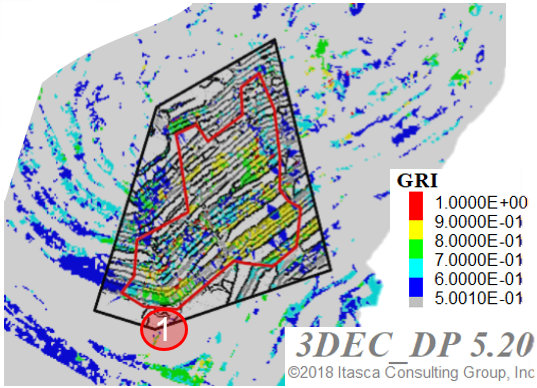

The GRI results shows two potentially high-risk areas in the Northeast and Northwest walls (Sector 1 and 2 with red lines in Figure 8).

Sector 1 shows a GRI contour between 0.7 and 1.0, mainly related to major faults and a structural fabric that is unfavorably oriented and generating planar failures. The hydrogeological condition shows a phreatic surface close to the slope surface and poor rock mass quality limiting Sector 1 by the west (halo of damage GSI~20 of a Principal Fault) as shown in Figure 9. The east corner of Sector 1 has a high potential risk (GRI=0.8-1.0) due to a fault that runs parallel to the slope and the unfavorable fabric orientation.

The GRI contour for the Northwest Wall (Sector 2 in Figure 6) shows a geotechnical risk due to a poor rock mass quality (GSI=20-30 Figure 9), several faults converging in that location and unfavorable orientation forming non-daylight wedges. Finally, the phreatic level is also very close to the slope surface.

A risk map provided by the mine shows high-risk areas (yellow lines, sectors A-G in Figure 8) reasonably similar to the GRI contour identified for sectors B and E. The rest of the sectors (A, D, F and G) seem not to be reproduced by the GRI. It must be emphasized that, simplistically, this particular case was not calibrated against the site-specific geotechnical features, and that the weighing factors were extracted from the Case 1 study, which would not be a recommended procedure for obvious reasons. Despite that, some reasonable proximity of results was observed, which is an encouraging result for validating the methodology.

Summary

- The proposed methodology seems to capture the relative geotechnical risk of an excavation based on a simplified combination of the key elements commonly involved in stability analyses.

- Whenever possible, a calibration process of the weighing factors specific for each site should be developed prior to predicting the behavior of any future designs.

- In the case that the necessary information for the calibration process is not available, this methodology could be used to perform a comparative analysis of the expected geotechnical risk conditions between alternative slope designs or for different pit walls at the same site.

- The tool should be used as a first pass test for planning formal slope stability analysis, as it allows to focus resources in higher relative risk areas.

- Further work needs to be conducted to add assessment of more complex mechanisms to the tool, but the initial results are encouraging.

References

Castro L., Cottrell B., Barker P. and Sintim K. (2011) “Application of GeoHazmap to the Pit Slope Design for the Detour Lake Project,” In Proceedings, International Symposium on Rock Slope Stability in Open Pit Mining and Civil Engineering (2011, Canada) Vancouver.

Hoek, E., Carranza-Torres, C. and Corkum, B. (2002) “Hoek-Brown failure criterion – 2002 Edition.” In Proceedings, NARMS-TAC Conference, 1, pp. 267-273. Toronto: University of Toronto Press.

Itasca Consulting Group Inc (2016). 3DEC (3-Dimensional Distinct Element Code, User’s Guide), Version 5.2. Minneapolis: Itasca.

Romana, M., Tomás, R., and Serón, J.B. “Slope Mass Rating (SMR) geomechanics classification: thirty years review” In: ISRM Congress 2015 Proceedings - International Symposium on Rock Mechanics, Quebec, Canada, May 2015.